Systems

Pools & Tanks

Home Bayset Systems Pool & Tank Systems Tiled Pools & Spas Waterproofing Tiled Swimming Pools & Spas – 625

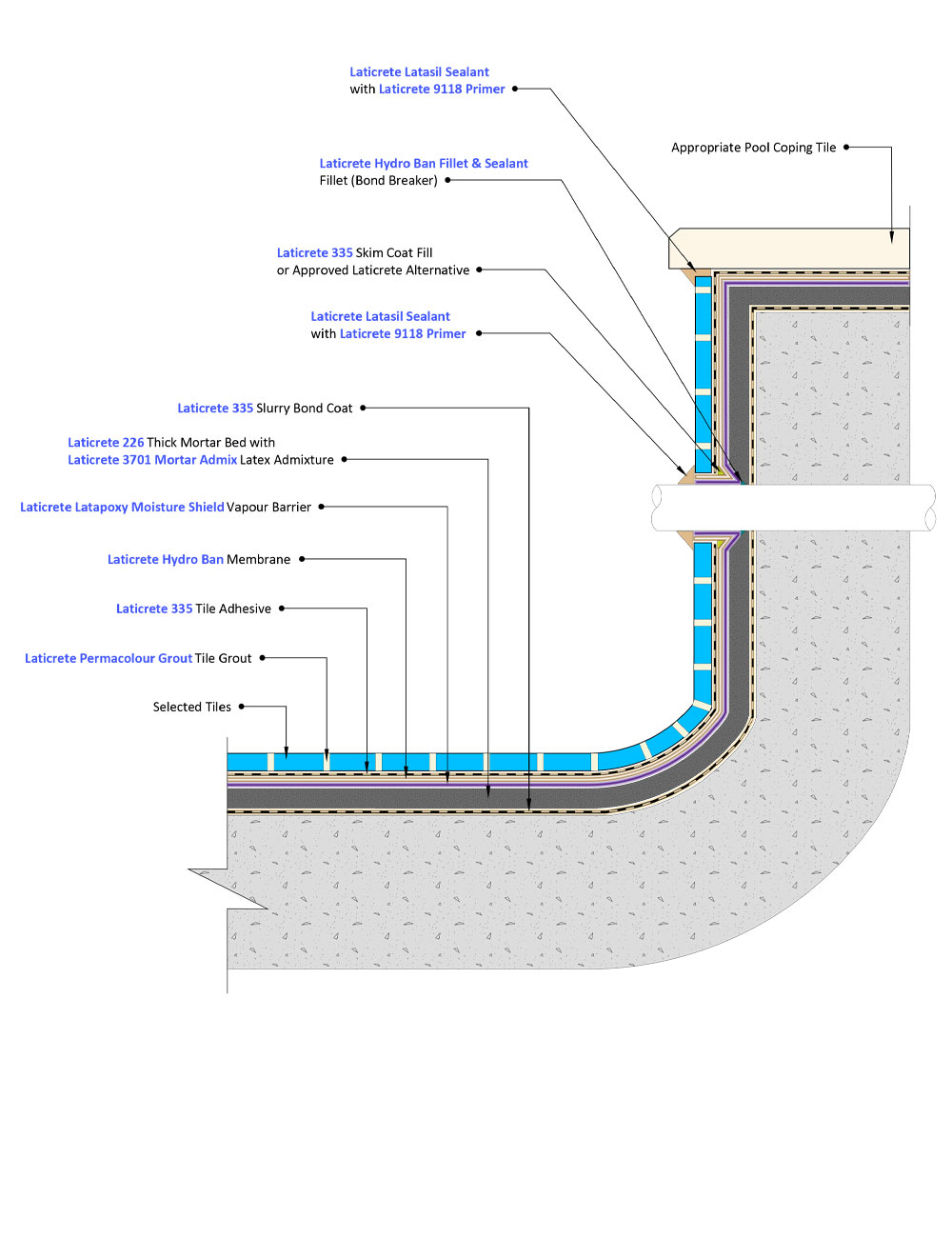

WP625 Waterproofing Tiled Swimming Pools & Spas

Preparation:

- All surfaces to be waterproofed must be firm, clean, dry, sound and smooth. All grease, oil, wax, curing compounds, loose material, paint and any other contaminants must be removed, masonry surfaces must be pointed flush and surface defects repaired. New concrete must be cured for a minimum of 28 days.

- External corners to be waterproofed must be bevelled to ensure a smooth transition of membrane from vertical to horizontal surfaces.

Installation:

- Apply LATICRETE 335 as a slurry bond coat to the pool structure prior to installing the screed.

LATICRETE 335 is a high-performance thin-bed adhesive for installing a wide range of tiles and stones.

- While the LATICRETE 335 slurry bond coat is still wet, Install LATICRETE 226 with LATICRETE 3701 Mortar Admix to achieve appropriate falls to waste. Note: Recommend creating a rebate around pipe penetrations to allow for adequate membrane adhesion.

LATICRETE 226 is a factory-prepared blend of carefully selected raw materials, Portland cement and graded aggregates. Designed for use with 3701 Mortar Admix to produce a latex Portland cement mortar that has exceptional strength.

LATICRETE 3701 Mortar Admix is a specially designed latex admixture for use with Laticrete 226 Thick Bed Mortar, thin-set adhesives, cement grouts, cement mortar beds and other cement mixes.

- Install an appropriate fillet (bond breaker) to all transitions using LATICRETE Hydro Ban Fillet & Sealant.

LATICRETE Hydro Ban Fillet & Sealant is a one-component, fast-curing, hybrid elastomeric adhesive and sealant, for use under Hydro Ban waterproofing membrane as a transition fillet and crack filler.

- Apply LATICRETE Latapoxy Moisture Shield vapour barrier to the substrate being waterproofed.

LATICRETE Latapoxy Moisture Shield is a 2-component, epoxy coating specifically designed to reduce moisture vapour emissions.

- Apply LATICRETE Hydro Ban membrane in a minimum of two coats to achieve the required dry film thickness. Ensure that the previous coat has completely dried before applying the subsequent coat(s). NOTE: All penetrations must be waterproofed.

LATICRETE Hydro Ban is a thin, load-bearing waterproofing/crack isolation membrane.

- Install tiles to the pool shell using LATICRETE 335 tile adhesive, including pool coping tiles.

LATICRETE 335 is a high-performance thin-bed adhesive for installing a wide range of tiles and stones.

- Grout tiles using LATICRETE Permacolour Grout.

LATICRETE Permacolour Grout is a high-performance, fast-setting grout.

- Seal all movement joints using LATICRETE Latasil Sealant, primed with LATICRETE 9118 Primer.

LATICRETE Latasil Sealant is a high-performance, one-component, neutral cure, 100% silicone sealant designed for ceramic tile and stone applications.

LATICRETE 9118 Primer is a one-component primer designed to increase the adhesion of Latasil to various substrates.

Products Used

- LATICRETE 335

- LATICRETE 226

- LATICRETE 3701 Mortar Admix

- LATICRETE Hydro Ban Fillet & Sealant

- LATICRETE Latapoxy Moisture Shield

- LATICRETE Permacolour Grount

- LATICRETE Latasil Sealant

- LATICRETE 9118 Primer