Systems

Planter Boxes

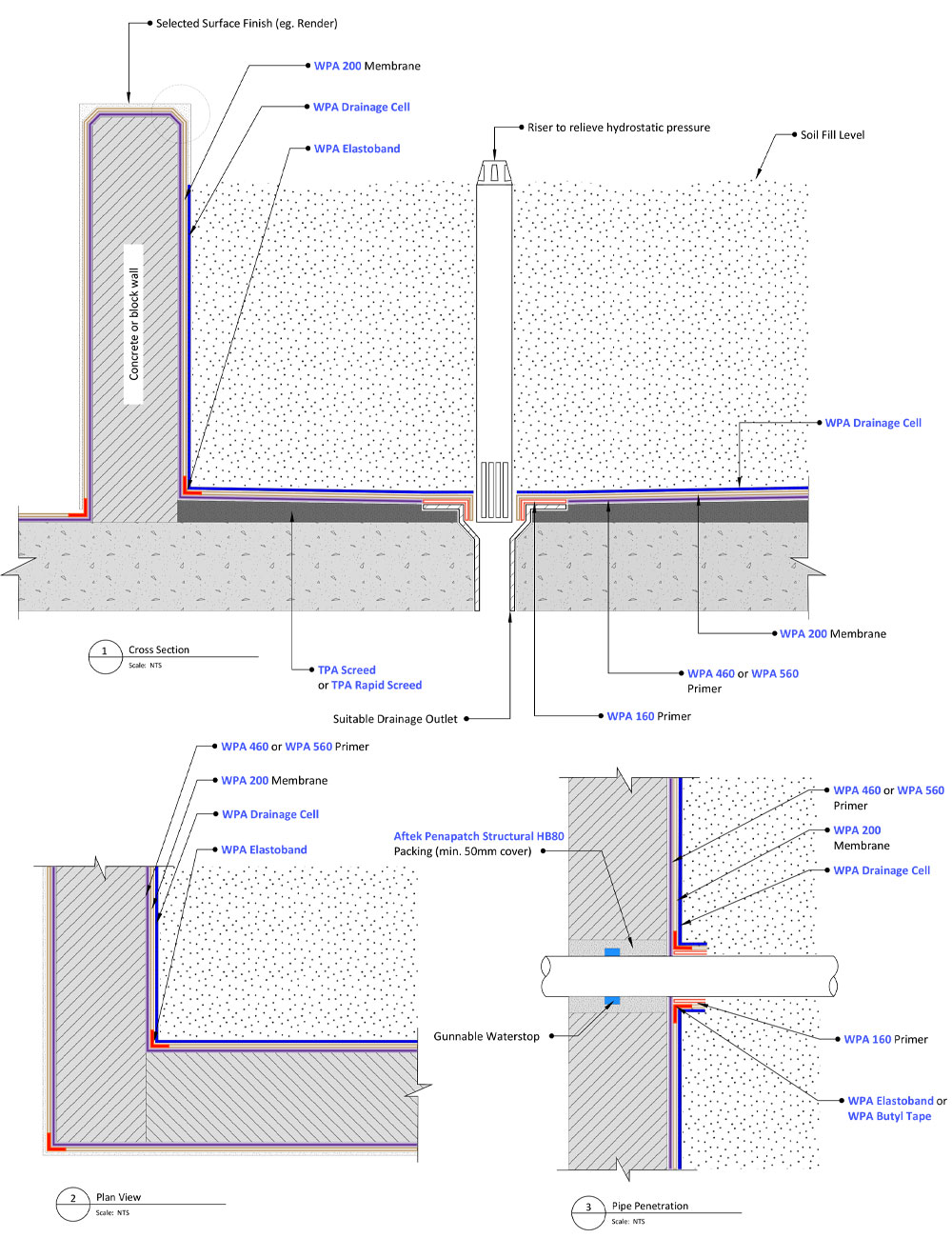

Home Bayset Systems Planter Box Systems Concrete Blockwork – Liquid Membranes Waterproofing Planter Box – Concrete Block (Cementitious) – 501

WP501 Waterproofing Planter Box – Concrete / Blockwork (Cementitious)

Preparation:

- All surfaces to be waterproofed must be firm, clean, dry, sound and smooth. All grease, oil, wax, curing compounds, loose material, paint and any other contaminants must be removed, masonry surfaces must be pointed flush and surface defects repaired. New concrete must be cured for a minimum of 28 days.

- External corners to be waterproofed must be bevelled to ensure a smooth transition of membrane from vertical to horizontal surfaces.

Installation:

- Waterproofing installation shall be in accordance with AS 4654.2 Waterproofing Membranes for External Above-Ground Use.

- Repair all surface defects with Aftek Penapatch Structural HB80.

Aftek Penapatch Structural HB80 is a high strength; high build shrinkage compensated structural repair mortar.

- Install a Gunnable Waterstop around all penetrations. The waterstop must be packed in between at least a 50mm cover of Aftek Penapatch Structural HB80. Gunnable waterstop products are caulk-grade, single-component swelling pastes used to stop water infiltration through concrete construction joints.

- Install TPA Screed to achieve appropriate falls to waste. Where a bonded screed is required, apply a bond coat using TPA 401M or TPA Lite. Install TPA Rapid Screed for an engineered or rapid set screed, using a bond coat of TPA Rapid for bonded screeds.

TPA Screed is a pre-blended screed mixture for the installation of cementitious screeds and tile beds, suitable for internal and external floor applications.

TPA Rapid Screed is a pre-blended, rapid set, engineered screed mixture for the installation of cementitious screeds and tile beds, suitable for internal and external floor applications.

- Install a puddle flange to all waste pipes, ensuring that puddle flanges are recessed into the substrate.

- Prime all non-porous substrates using WPA 160 primer, such as puddle flanges and PVC pipes.

WPA 160 is a specialised solvent-free primer designed for enhancing the adhesion of subsequent membranes, adhesives, toppings and decorative finishes over non-porous substrates.

- Apply WPA 460 or WPA 560 primer to the substrate being waterproofed.

WPA 460 is a two-part, water-based epoxy primer, used to seal concrete and masonry surfaces.

WPA 560 is a two-part, water-based epoxy primer, designed as a water and vapour-proof coating under waterproofing membranes.

- Apply WPA 200 membrane in a minimum of two coats to achieve the required dry film thickness. Ensure that the previous coat has completely dried before applying the subsequent coat(s).

NOTE: All penetrations must be waterproofed. Membrane must be sealed to and terminate into the puddle flange, and extended vertically to a minimum of 100mm above the expected soil fill level where the planter box abuts a wall.WPA 200 is a flexible, two-part, rapid-drying, cementitious waterproofing membrane system, specifically designed for use under tile, stone and exposed applications.

- All transitions must be detailed utilising WPA Elastoband or WPA Butyl Tape.

WPA Elastoband is an innovative detailing system designed for waterproofing and sealing all types of joints, junctions and transitions subjected to movement.

WPA Butyl Tape is a multi-purpose self-adhesive detailing tape incorporating a fleece face layer with a release backing film and self-adhesive butyl rubber on the underside. It provides a waterproof seal between most types of joints and transitions in both internal and external applications

- Continue the WPA 200 membrane over the open edges of the planter box. Externally exposed walls of planter boxes must be waterproofed to prevent failure of the internal planter box membrane.

- Install WPA Drainage Cell to all waterproofed surfaces below soil level.

WPA Drainage Cell is a two-core drainage sheet consisting of a non-woven geotextile filter layer thermally welded to a water-impermeable, recycled HDPE (High-Density Polyethylene) drainage membrane.

- Install an internally filtered riser for the purpose of relieving hydrostatic pressure.

- Ensure that the membrane that extends above the soil fill level is protected from UV damage by selected surface finishes or capping material.

Products Used

-

Aftek Penapatch Structural HB80

- TPA 401M

- TPA Lite

- TPA Rapid Screed

- TPA Screed

- WPA 160

- WPA 460

- WPA 560

- WPA 200

- WPA Elastoband

- WPA Butyl Tape

- WPA Drainage Cell