Systems

Flooring

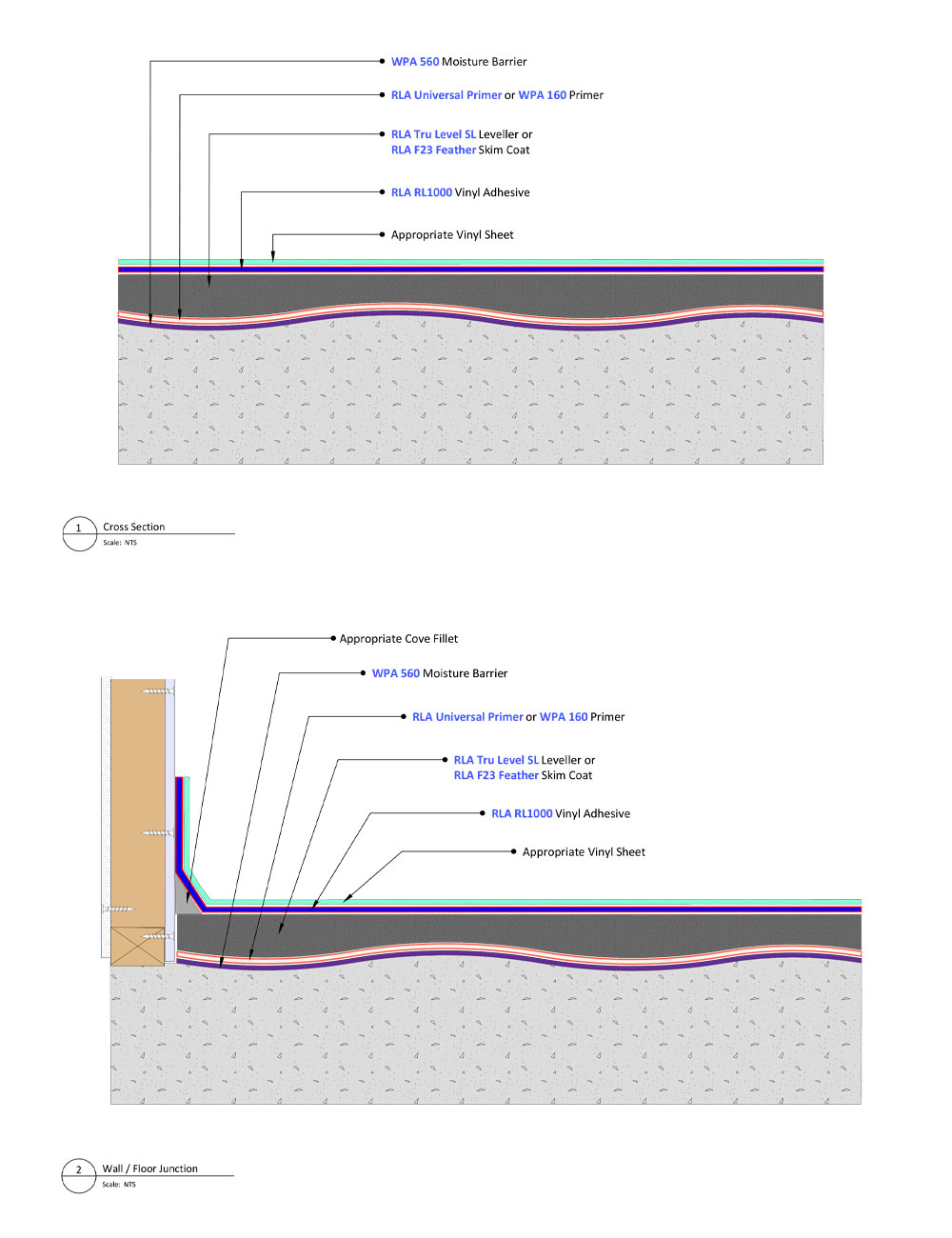

Home Bayset Systems Flooring Systems Sheet Vinyl Systems Floorcoverings – Vinyl Sheet – 700

FL700 Floorcoverings – Vinyl Sheet

Preparation:

- Substrates must be firm, clean, dry, and sound. Substrates and subfloors must be free of grease, oil, wax, curing compounds, high levels of moisture (hydrostatic pressure), loose material, paint and any other contaminants. New concrete must be cured for a minimum of 28 days.

- Thoroughly vacuum loose material and dust.

- If mechanical preparation is required, prepare the floor using the recommended methods as advised by the substrate manufacturer.

- For concrete floors, moisture content and relative humidity tests should be conducted prior to installation.

Installation:

- Vinyl installation shall be in accordance with AS 1884 Floor Coverings – Resilient Sheet and Tiles – Installation Practices.

- Apply WPA 560 as a moisture & vapour barrier, if relative humidity tests show moisture above 80%, or hydrostatic pressure and rising dampness are present.

WPA 560 is a two-part, water-based epoxy primer, designed as a water and vapour-proof coating under waterproofing membranes.

- Apply RLA Universal Primer or WPA 160 on all non-porous substrates, including where WPA 560 has been used.

RLA Universal Primer is a rapid-drying, solvent-free, low VOC, water-based acrylic primer.

WPA 160 is a specialised solvent-free primer designed for enhancing the adhesion of subsequent membranes, adhesives, toppings and decorative finishes over non-porous substrates.

- Apply RLA Universal Primer on all porous substrates.

- Where required on uneven surfaces of 1 – 30mm, install RLA Tru Level SL on primed areas.

RLA Tru Level SL is a specially formulated floor-levelling compound with excellent flow properties, used for levelling differences from 1mm to 30 mm in thickness in a single application on new or existing internal substrates.

- Apply a skim coat of RLA F23 Feather to all primed surfaces from featheredge to 3mm, where required.

RLA F23 Feather is a rapid-drying cement-based skim and smoothing compound providing a smooth finish and even surface to a variety of internal substrates prior to the application of floor coverings.

- If coving is required, install a preformed cove fillet using RLA Brush Contact Adhesive.

RLA Brush Contact Adhesive is a high-quality brushable grade solvent-based (flammable), rapid-drying contact cement, which has high strength, excellent aging and heat resistance.

- Once the levelling compound has cured, apply a layer of RLA RL1000 with a notched trowel. Ensure to apply only the amount of adhesive that can be covered within the open time.

RLA RL1000 is a single-part, VOC-compliant, isocyanate-free, water-resistant, resilient flooring adhesive.

- Install the vinyl sheet into a wet film of adhesive and dry roll on top of the vinyl sheet in a cross-hatch motion to ensure the adhesive transfers onto the backing of the sheet vinyl.

- Ensure all laps are heat welded together and weld rods are levelled with the vinyl sheet.

Products Used

- WPA 560

- RLA Universal Primer

- WPA 160

- RLA Tru Level SL

- RLA F23 Feather

- RLA Brush Contact Adhesive

- RLA RL1000